Cài đặt điện áp:

Quá áp: 60V 200V 400V

Áp suất thấp: 48V 160V 320V

Lỗi cài đặt: ≤±3%

Hệ số hoàn trả: ≥0,85

Thời gian trả về: 1,2 lần ≥0,15s3 lần ≥0,03s

Công suất liên lạc: DC50WAC250VA

Hình thức liên hệ: di chuyển và đóng, di chuyển và đóng và phá vỡ,

Hai bước ngắt chuyển động đóng, hai chuyển động đóng chuyển chuyển ngắt

Kích thước mở: 107,5×62,5mm

Phương pháp cài đặt: Áp dụng vỏ A11K, A11H, A11Q

DY-30 series voltage relays, used in relay protection lines as operating elements for overvoltage protection or low voltage latching.

Structure and principle

1. The relay is electromagnetic and operates instantaneously. The magnetic system has two coils, the head of which is connected to the base terminal.

2. The calibration value and rating of the relay name brand are in units of V when the coils are in parallel.The action value of the relay can be changed by turning the pointer on the dial to change the reaction moment of the hairspring.

3. Relay action: For over-voltage relay, when the voltage rises to or exceeds the setting value, the relay will act, and the moving closing contact will close, while the moving breaking contact will break.When the voltage drops to 0.8x setting value, the relay returns, the moving closing contact disconnects and the moving breaking contact closes. For the low-voltage relay, when the voltage drops to the setting voltage, the relay operates, the moving closing contact disconnects and the moving breaking contact closes.

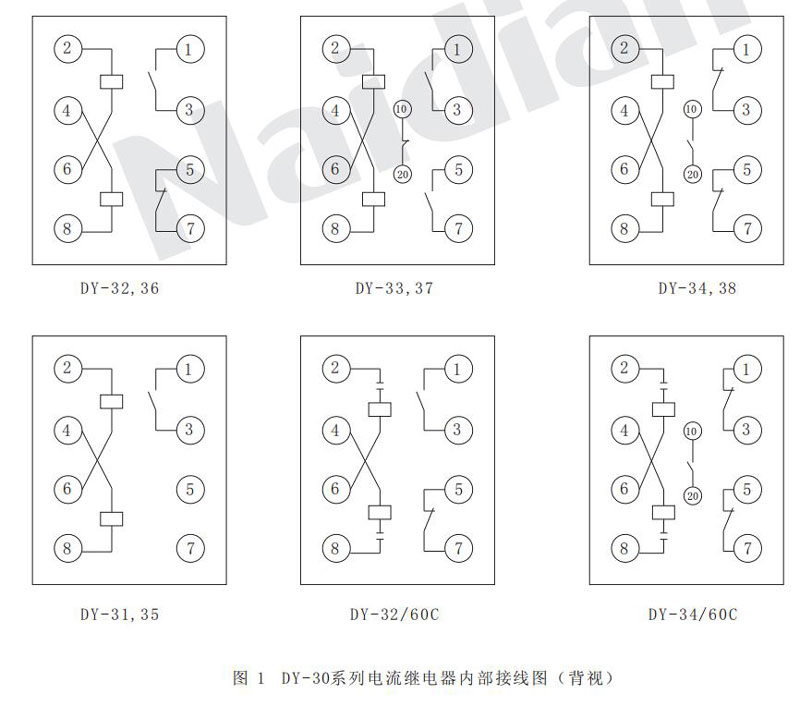

4. See Figure 1 for the internal wiring diagram of the relay.

Figure 1 Internal wiring diagram of DY-30 series current relay (back view)

Use and maintenance

1. Before the use of the relay, the casing shall be removed and the machine shall be pulled out to check whether there is any damage caused in transportation;If the moving plate touches the magnetic plate, the coils of the spring thread collide, and the friction on the shaft of the moving plate, for this reason, set the pointer of the relay at the first point, rotate the movable system in the direction of the magnetic plate by hand, and then let go. The movable system should be turned back to the original balance position until the stop, and then make necessary adjustment and setting.

2. When the relay is readjusted, it must be guaranteed.

2.1 The axial activity of the movable system is between 0.15-0.3mm.

2.2 The air gap between the moving plate and the magnetic pole shall ensure that the moving plate and the magnetic plate shall not collide under any specified working conditions of the relay.

2.3 For relays with moving and breaking contacts, bridge contacts shall not touch moving and breaking contacts at the same time in the process of operation.

2.4 When the pointer rotates from the first scale value to the final scale value, the rings of the hairspring shall not touch.

2.5 When the relay operates, the popular contact should slide (tolerance +1mm) on the center line of the static contact and move.The total air gap of static contact is not less than 2mm.

2.6 The distance between the stationary contact and the limiting piece shall not be greater than 0.3mm.

2.7 When adjusting the operation value of the relay, the adjustment of the minimum setting value is mainly to change the reaction force of the hairspring, while the adjustment of the maximum setting value is mainly to change the air gap between the moving plate and the magnetic plate.

2.8 The relay shaft and bearing shall not be lubricated.

2.9 It is not allowed to use sandpaper or other rough materials to clean the contacts. It is advisable to use a sharp blade or clean the contacts, and then wipe them with a clean and soft cloth to avoid touching the contacts with fingers.